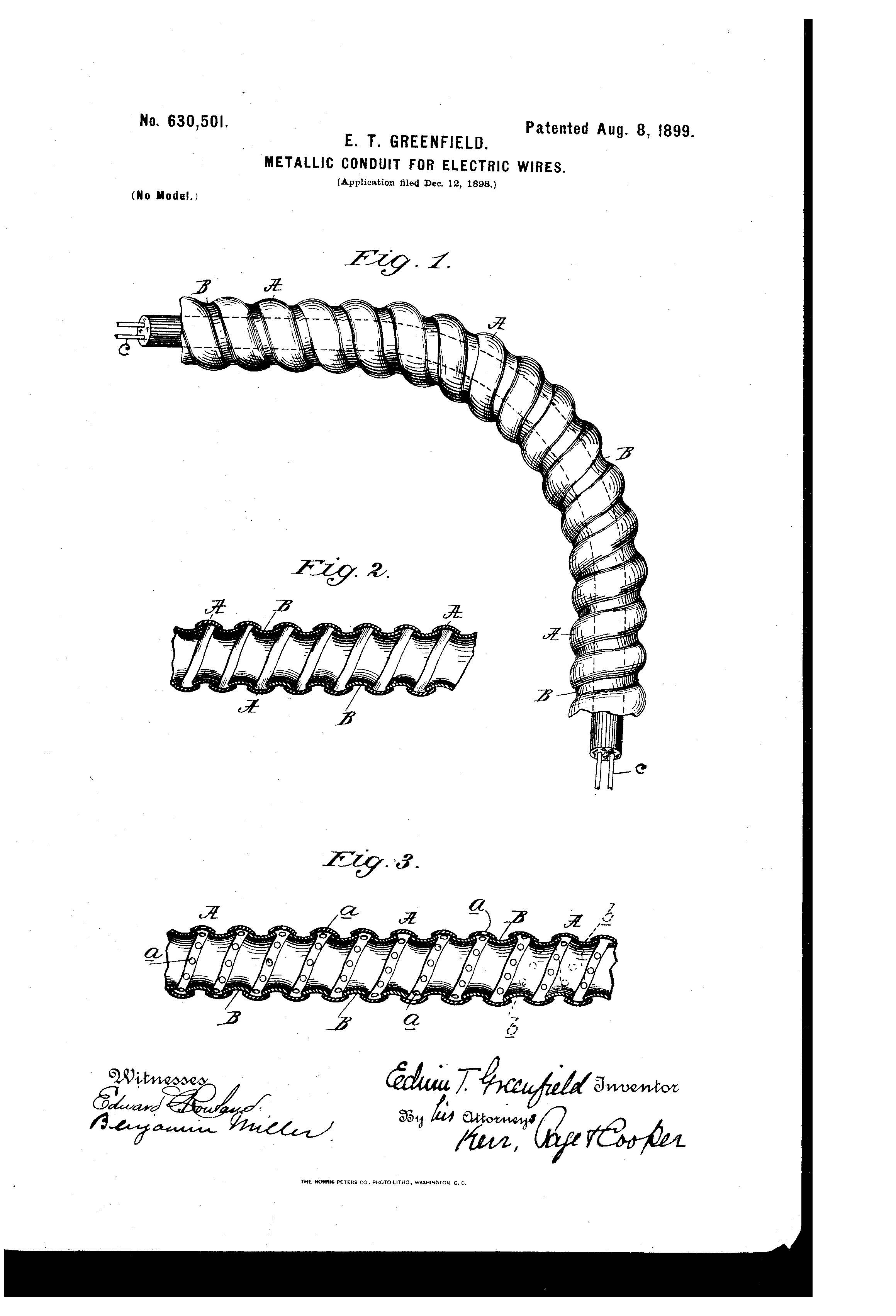

On this day in 1899 Edwin T. Greenfield was granted the patent for Metallic Conduit for Electric Wires. U.S. Patent No. 630,501.

As heretofore used metallic conduits for containing electric wires have been made air-tight and water-tight and particularly where the interiors of such conduits have been lined with an insulating substance, the object being to prevent the oxidation of the pipe and injury to or deterioration of the insulating lining. The use of such conduits has been attended with certain practical difficulties – namely, changes of temperature have produced internal sweating of unlined conduits, and as no means were provided for the ventilation of the same the moisture injuriously affected the insulation of the wires and caused the oxidation of the pipe; but the most serious difficulty was that the presence of the moisture was liable to produce a short circuit between the electric wires themselves or between the wires and the metal pipe. When this occurred with currents of large amperage, the gases which were developed by the heat produced by the short circuits would expand until the conduit would burst. This rupture usually occurred at the heated spot, and the hot metal and burning particles of insulating material were scattered through the surrounding space or apartment and were liable to produce a destructive fire. This danger is insidious, since the short circuit is liable to take place in the walls of unoccupied rooms or when concealed in remote places, so that the resulting fire has an opportunity to gather headway before it is detected. This invention is particularly designed to guard against these dangers; and it consists in a metallic conduit vented radially in all directions throughout its length, so as to permit the free circulation of the atmosphere to its interior and to provide an outlet for the gases generated by a short circuit, so that they cannot collect in sufficient volume to create so an explosion. As a result of this construction the chances of fire from a short circuit between the electric wires in the conduit or between the wires and the conduit itself are greatly reduced, for while the metal may become highly heated, so that in certain positions it might set fire to adjacent woodwork, yet the process would be relatively slow and the fact and location of the short circuit would be disclosed by the smoke coming through the vents in all directions. The ventilation of the conduit also secures immunity from oxidation, for in case moisture should collect in the interior it is speedily dissipated by the circulation of the air there through, and in this way the chief cause of short-circuiting is avoided, as well as the oxidation of the pipe and of the insulation of the wires.